Company R & D Technology

Our Company attaches great importance to the development of new products, and has established long-term and stable technical cooperative relations with many domestic universities and research terms of engineering projects, we keep close contact with Luoyang engineering construction company (LPEC), SINOPEC engineering construction company (SEI), China petroleum engineering construction company east China design company (CEI), as well as foreign experts and professors from the United States, France and Russia have been invited to our Company for communication. Through a variety of forms communication and cooperation, further promoting our Company product development and technical innovation.

Our Company technology R & D center includes dynamic simulation laboratory, static physical and chemical analysis laboratory, high pressure testing room and intellectual property management office.

Company owns a set of dynamic bench test equipment for two-stage AC dehydration and desalting. A set of three-stage ac/dc and high-speed electric dewatering and desalting dynamic bench test equipment; A set of dynamic bench test equipment for IGF induced air floatation and NSF walnut shell filter oily wastewater treatment; One set of high frequency intelligent response dynamic bench test device; One set of demulsifier synthesis test equipment; An emulsion stability tester (EST) imported from the United States.

These experimental devices can not only directly observe the accumulation and settling process of water droplets under the action of high-voltage electric field, but also output the current and voltage variation curve in the high-voltage electrostatic separation process, which provides an important design basis for the engineering design of electric desalting equipment.

Technology R & D in Company Core Products-Electric Desalter and Dehydrator

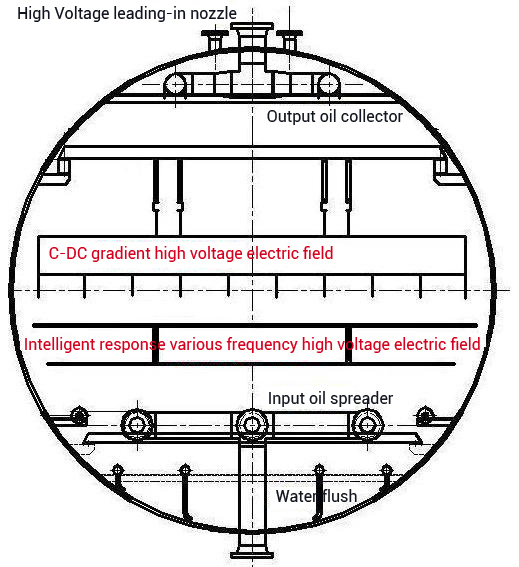

The 20kV high voltage is safely introduced into the metal tank filled with inflammable and explosive oil to form a high-voltage electric field with different electric field intensity, and the high-voltage electric field is used to separate the oil and water from the emulsion.

First generation of electric desalting technology: AC desalting technology

1. Two or three layers of electrodes are designed in the tank to form two or three electric fields

2. Simple structure, good stability and reliability.

3. The desalting and dehydration rate can meet the requirements of the low-requirement process.

4. High power consumption.

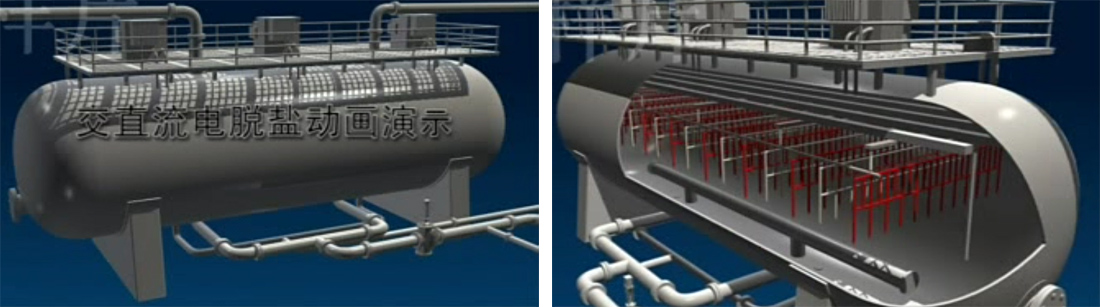

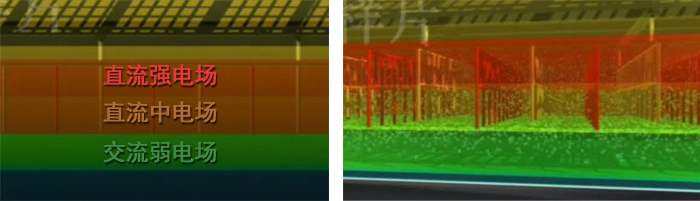

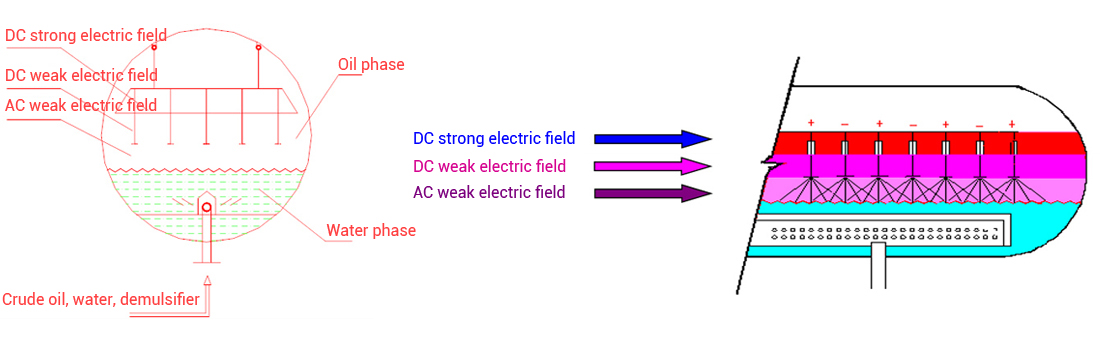

Second generation electric desalting technology: AC-DC electric desalting technology

The positive and negative vertical pole-varying electrode plates are successively arranged along axial direction of tank. Utilizing AC and DC electricity to remove water droplets utilized. Reasonable electric field layout and high dehydration rate, with good adaptability to various oil quality.

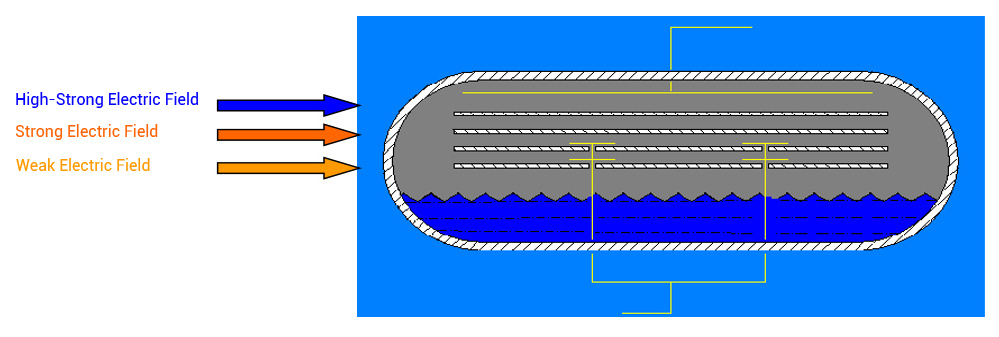

Third generation electric desalting technology: high speed electric desalting technology

Four layers of electrode plates are arranged inside the tank; Form a weak electric field, two strong electric fields, a high-strong electric field; Small tank size with amount handling capacity; High rate of desalting and dehydration; with good adaptability to various oil quality.

Fourth generation electric desalting technology: intelligent response electric desalting technology

It can adjust the high-voltage electric field in DCS control center, and has the functions of remote diagnosis and intelligent regulation. The intelligent control software forms the software copyright.

Fifth generation of electric desalting technology: Dual-frequency & AC-DC Comprehensive Electric Desalting Technology

Especially for the treatment of desalting and dehydration of heavy and inferior crude oil, two different forms of high-voltage electric fields are designed in the tank body, among which an intelligent high-voltage electric field with variable frequency response is designed at the oil-water interface which is easy to emulsify.

The technology has been used in the scientific and technological projects of CNPC and SINOPEC and in the treatment of heavy crude oil abroad.

Second prize of science and technology progress of Federation of Petroleum and Chemical Industries. Third prize of science and technology progress of Jiangsu Province. Third prize of science and technology progress of China Petrochemical Corporation.

Currently, Company owns 10 authorized patents and 1 computer software copyright.

In 2017, "Intelligent Response Electric Desalter/Dehydrator Device and Control Method" won China national excellent patent award.